In Search for an Ideal Pump

The hearth of flow analyzer is the pump and therefore the development of Flow injection is entwined with development of fluid drives.

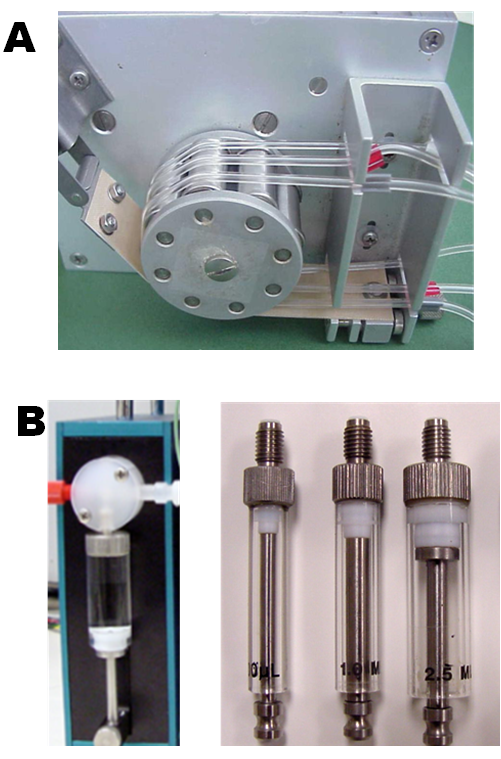

Peristaltic pumps (A) are still the most frequently used drives for FI systems, because they generate continuous flow in several parallel channels, where flow rates can be easily adjusted by rotation rate of a drum and by I.D. of the peristaltic tubing. Contributing to the popularity of peristaltic pumps is their apparent low cost, although the price of consumables – the peristaltic tubing- exceeds many times the price of the pump over its lifetime. The largest drawback of peristaltic pumping is the elasticity of the tubing, causing flow rate to decrease during use. Therefore, the instrument has to be frequently calibrated and peristaltic tubing has to be replaced.

Stepper motor driven syringe pumps (B), are free from drawbacks of peristaltic pumps, they generate a highly reproducible flowrates over long periods of use, without need for servicing. Syringe pumps are durable and chemically resistant, but their drawbacks is their inability to generate a continuous flow beyond the capacity of the syringe. Refilling of the syringe is a drawback, compared with peristaltic pumping, since it disrupts the flow, and for serial assays decreases sampling frequency.

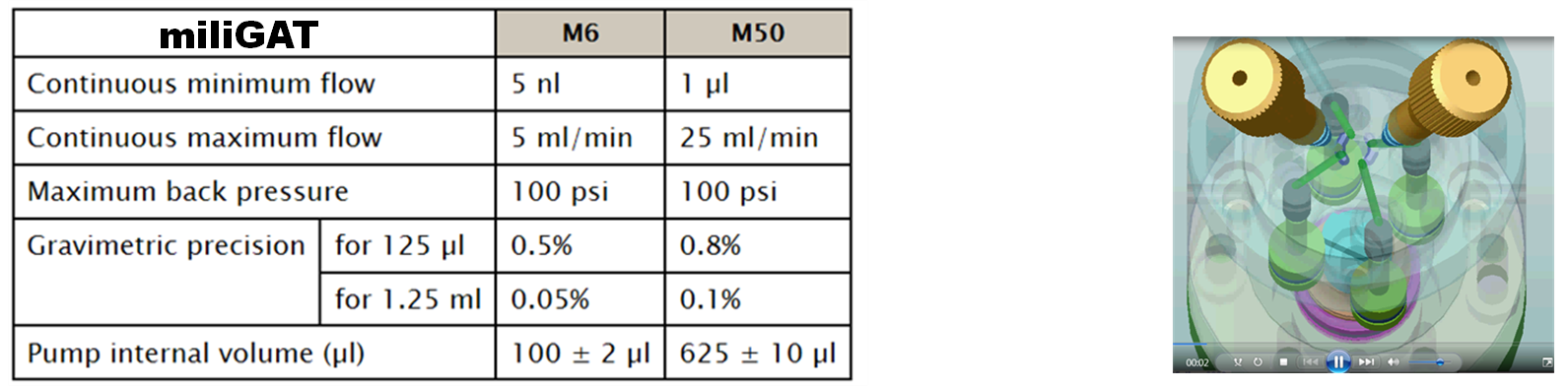

miliGAT pump (C) represents the recent advance in fluid drives. It combines advantages of peristaltic pumping, the continuous refilling, with all advantages of a syringe pump. It provides a wide range of flow rates, in forward and reverse direction and is computer compatible. It unique construction is based on four micro syringes that are moved around on a slanted carousel, the speed of which controls the flowrate, and the degree of rotation the delivered volume.

1.4.7.

C